E-Mail-Formatfehler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

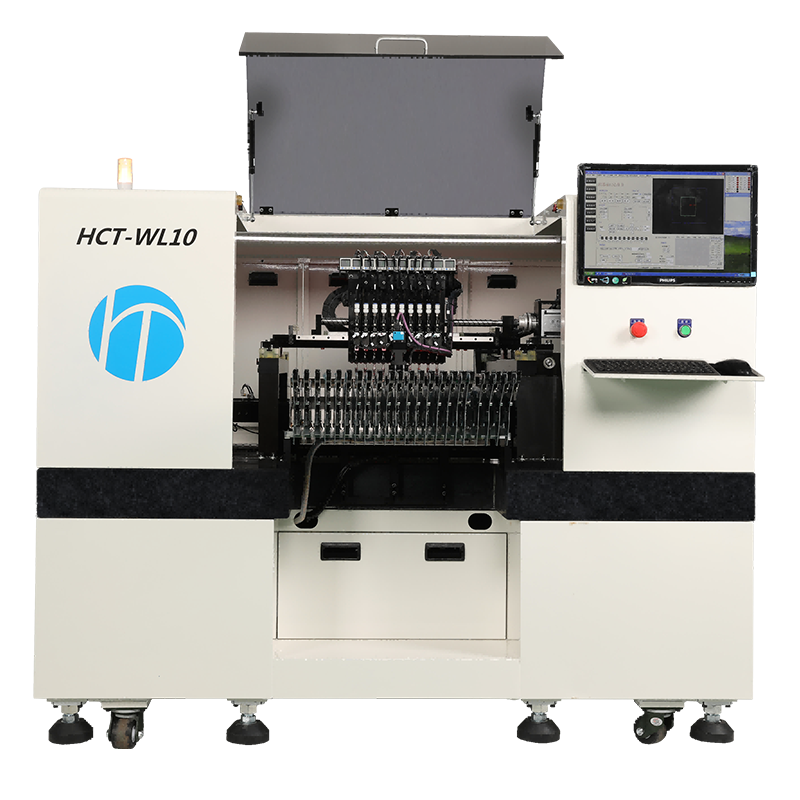

HCT-550LV Automatic 10 Heads LED Chip Mounter

The machine is built with high-quality hardware components from renowned brands, ensuring long-term reliability and durability. This results in reduced maintenance requirements and increased machine uptime, contributing to overall operational stability and customer satisfaction.

The chip mounter is equipped with a flying vision alignment system, featuring bottom fixed cameras for precise component placement. With 10 spindles and a single gantry, this machine offers efficient and accurate LED chip mounting. It can achieve a placement speed of up to 55,000 CPH (Optimum) with a placement accuracy of ±0.05mm.

P&P Machine Standard Spare Parts List:

No. Specifications Qty

1. Electric Feeder 8MM 10

2. Samsung Nozzles 30

3. Hexagon Wrench Tool 1

4. Material Rack 1

Product Features

- Advanced Flying Vision Alignment System: The HCT-550LV now incorporates an advanced flying vision alignment system with bottom fixed cameras. This technology ensures even higher placement accuracy and precision, resulting in superior quality LED chip mounting.

- Increased Component Range: The machine now supports an expanded component range, including smaller components such as 0201 chips. This allows for greater flexibility in LED chip mounting and accommodates a wider range of product requirements.

- Enhanced Placement Speed: With optimized algorithms and improved mechanical design, the HCT-550LV achieves an even higher placement speed. It can now reach up to 60,000 CPH (Optimum), enabling faster production cycles and increased productivity.

Specification

|

Model |

HCT-550LV |

|

|

Alignment |

Flying Vision Alignment System (Bottom Fixed Cameras) |

|

|

Number of Spindles |

10 Spindles x 1 Gantry |

|

|

RatedPlacement Speed |

Vision Alignment |

LED 2835 55,000 CPH (Optimum) |

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

|

|

Mechanical Precision |

±0.02mm |

|

|

Component Range |

Fly Camera |

0603(inch)~5050~7474(mm), high-power LED,IC<10mm |

|

Max Height |

H=18mm |

|

|

Board Dimension(mm) |

Minimum |

50(L) x 50(W) |

|

Maximum |

1200(L) x360(W) 1500(L) X 360(W) Optional |

|

|

PCB Thickness |

0.5 - 3.0 |

|

|

Board Handling Method |

Inline Conveyor |

|

|

Tape Feeder |

Feeder Type |

ElectricFeeder |

|

Feeder Capacity |

26 (12mm Standard) |

|

|

Optional |

8mm, 12mm, 16mm, 24mm |

|

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

Max3.5KW |

||

|

AirSupply |

Built-in Vacuum Pump (for nozzles only) |

|

|

Mass |

Approx.1560kg |

|

|

External Dimension(mm) |

2,000(L) x1,250(D) x 1,400(H) |

|

Product Advantages

1.Improved Efficiency: The advanced features of the HCT-550LV, such as the flying vision alignment system and increased placement speed, significantly enhance production efficiency. This results in shorter lead times, reduced manufacturing costs, and improved overall operational efficiency.

2.Superior Placement Accuracy: The machine’s high-precision placement technology ensures exceptional accuracy, with a placement accuracy of ±0.05mm. This guarantees consistent and reliable placement of LED chips, minimizing the risk of defects and improving product quality.

3.Cost Savings: The HCT-550LV offers cost-saving benefits through its automatic nozzle change function. This feature eliminates the need for manual nozzle changes, reducing downtime and increasing production efficiency.

Product Display